Closed pressing-system with hermetically sealed door / TPG:

At the closed pressing-system with hermetically sealed and pneumatic door the winepress provides all the advantages of a tank-press. Additionally the possibility to herterodyne the mash with gas to establish an anoxyic zone and to avoid oxidation.

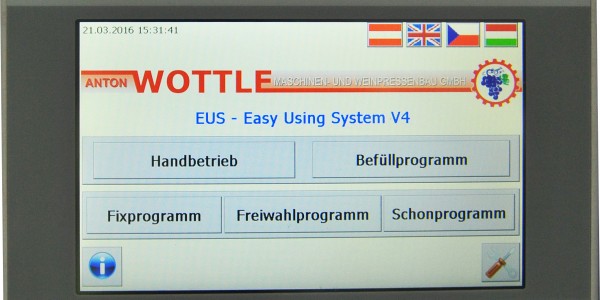

- self-explanatory pressing program – operation via touchpanel

- different pre-programmed fixed programs

manual control or free progammable pressing programs, pectin-program,

whole grapes-pogram, flavour-programm, red-wine-program, primary-program „Grand Reserve“ - optional interface for external acess-uni e.g..: PC oder laptop

- Display of maintenance intervals and error messages

- Suggestions for troubleshooting on the display

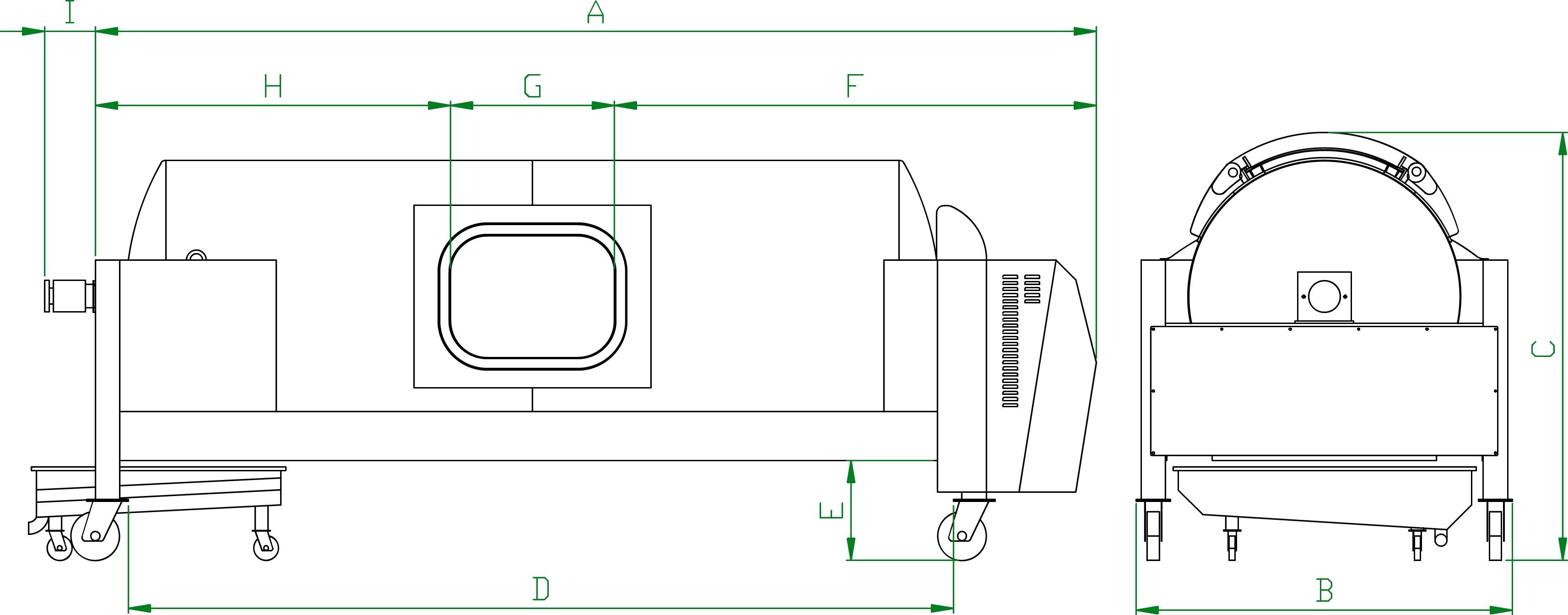

- Pneumatically actuated shunting door with inflatable seal — including

pneumatic rotary feedthrough - Open frame construction made of shaped-tube frame

- Sliding guide plate on the shaped-tube frame for selective pomace discharge — as of TPG 2600

- Gentle start with frequency converter

- Pomace-discharge strip with TPG 3000, 5000, 6000, 7500, and 10000

- Basket opening with TPG 2200: 670 mm x 500 mm — one longitudinally slideable rectangular door on the basket

- Basket opening with TPG 2600–TPG 10000: 920 mm x 500 mm — one longitudinally slideable rectangular door on the basket

- external air-supply

- Clean-Manaell-Unit for easy quick-cleaning

- Pressing in a sealed atmoshere (CO2)

- disc valve for controlled juice drainage

- Cooling jacket for the press basket

- Level control for juice tray

- external control

- PC-interface

- gravity funnels

- individual chutes

- sliding tubs

- custom-made overall plants

Describtion

- Design completely in stainless steel

- hermetically sealed pressing programm

- Permanently mounted compressor and pre-pressure blower (also possible externally)

- Large geared motor (low-noise operation)

- Tight pneumatic door

- Frequenc controlles start-up

- Pressing membrane of polyurethane (suitable for foodstuff)

- Membrane exactly cut to size without creasing

- 3 filling programs (careful filling, fresh must, whole grapes)

- Pre-programmed filling position – loading from above

- Pre-programmed emptying position

- Free programmable cleaning position

- Easy cleaning

- Smooth pomace discharge

- Simple and quick cleaning because of fully welded parts